More Projects

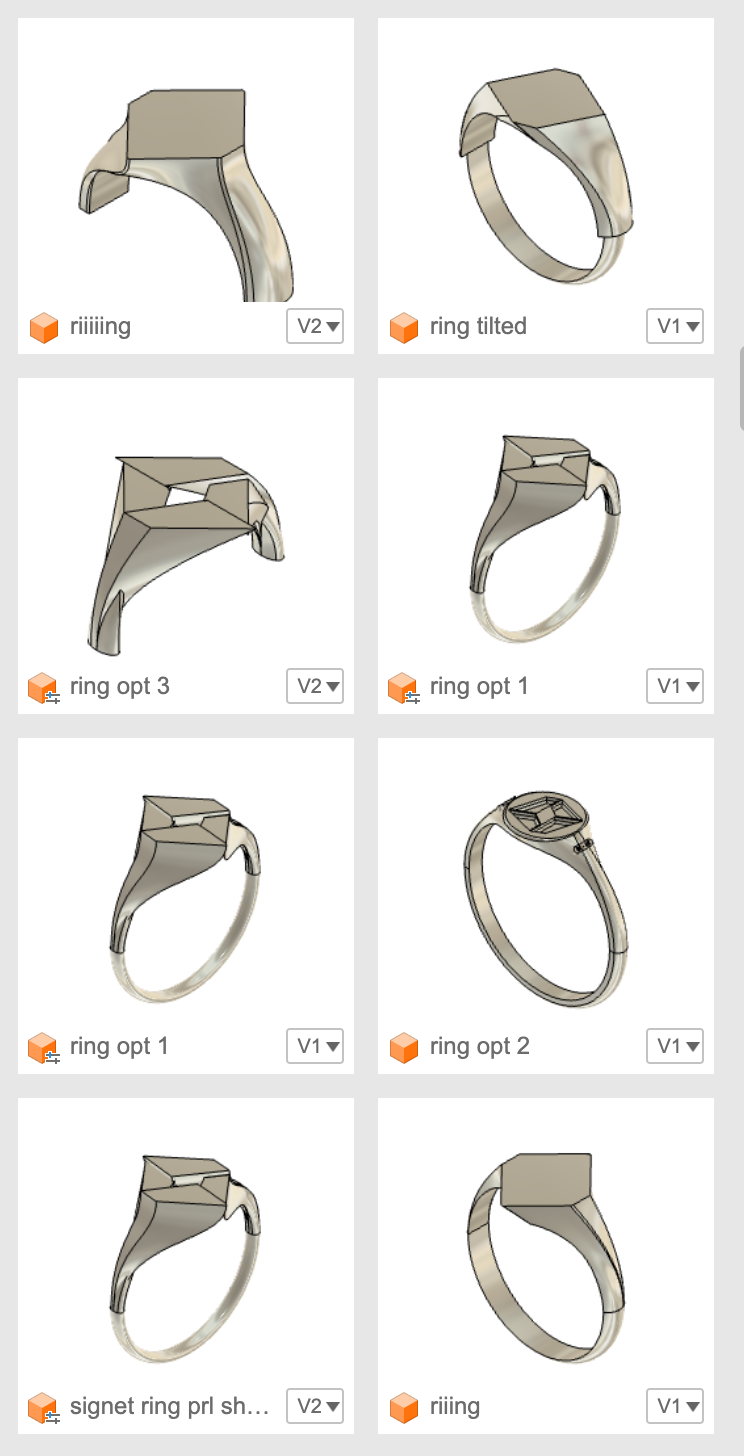

PRL Training Ring

PRL Training Ring

A silver ring used to teach the course assistants at the Product Realization Lab (PRL) silversmithing techniques. Design incorporates PRL logo and is parametrically designed to be cast in any ring size.

Designed with Sara Shaughnessy and Amanda Knox-Sather

Processes: investment casting, parametric CAD modeling, resin printing, finishing

Timeframe: 10 weeks

Materials: sterling silver

Learnings: robust CAD design practices, iteration in CAD and on paper, worked in instructor role to elevate silversmithing standards of the lab, designed ring as educational tool

Injection Molding

Injection Molding

Projects for Stanford’s ME 325: Injection Molding. A skeleton charm for use in a linked chain. An overmolded faux-gem setting for a custom necklace.

Processes: CAD modelling, mold flow, CNC machining, injection molding

Timeframe: 10 weeks

Materials: Polypropylene, TPE

Learnings: Moldflow for part molding success, designing under injection molding process constraints, running the machine to get an intuitive sense of injection molding parameters, machining tiny features in aluminum mold blocks.

Tortugita

Tortugita

Project for Stanford’s ME 103: Design and Manufacturing. A turtle-shaped pincushion cast out of silicon bronze and post-processed on the mill.

Processes: Sandcasting, woodworking, wood turning, manual milling, finishing

Timeframe: 10 weeks

Materials: Silicon bronze, modulan, fabric, foam, acrylic

Learnings: This was my introduction to manufacturing - a class I went on to TA several years later! Learned how to turn on a lathe (metal + wood), how to mill, how to sandcast (bronze + aluminum), how to oxy-acetylene weld, and work with sheet metal. I learned to consider manufacturing during the design process and how to work around those limitations

Silversmithing Coursework

Silversmithing Coursework

A sampling of my work from all 3 silversmithing courses taught at Stanford, as well as a metalsmithing apprenticeship in Nicaragua. I have gone on to TA each of these courses for 6 sessions from 2023-2025. These works are a variety of silver, bronze, and gold parts.

Processes: Investment casting, wax carving, fabrication, finishing, inlay

Learnings: Doing many projects has given me many opportunities to expand the breadth of my design experience and try different processes and specialty skills (inlay, moldmaking, metal turning, etc). With each new project I undertake, I hope to learn a new skill. This has been invaluable in enabling me to expand the types of designs I can create.

Mechatronics

Mechatronics

Project for Stanford’s ME 210: Introduction to Mechatronics. A ball delivery robot designed to run a course and score points against an opponent robot. Uses a magnetometer for heading localization and motor encoders for distance measurement.

Processes: Electronics component selection, firmware, laser cutting

Timeframe: 10 weeks

Learnings: integrating electronics with mechanical systems, the importance of state diagrams in planning autonomous operation, designing for ease of iteration in addition to end performance

Mechanical Systems Design

Mechanical Systems Design

Group project for Stanford’s ME 104: Mechanical Systems Design. A robot to carry a load upward between two beams. Used a provided low power motor, a custom geartrain, and a mass-efficient chassis.

Processes: 3D printing, FEA, CAD design, mechanical analysis

Timeframe: 10 weeks

Materials: Formlabs resin, PLA, assorted hardware, wood

Learnings: minimizing mass on a load-carrying structure, designing for easy assembly and testing, designing for meeting a functional requirement

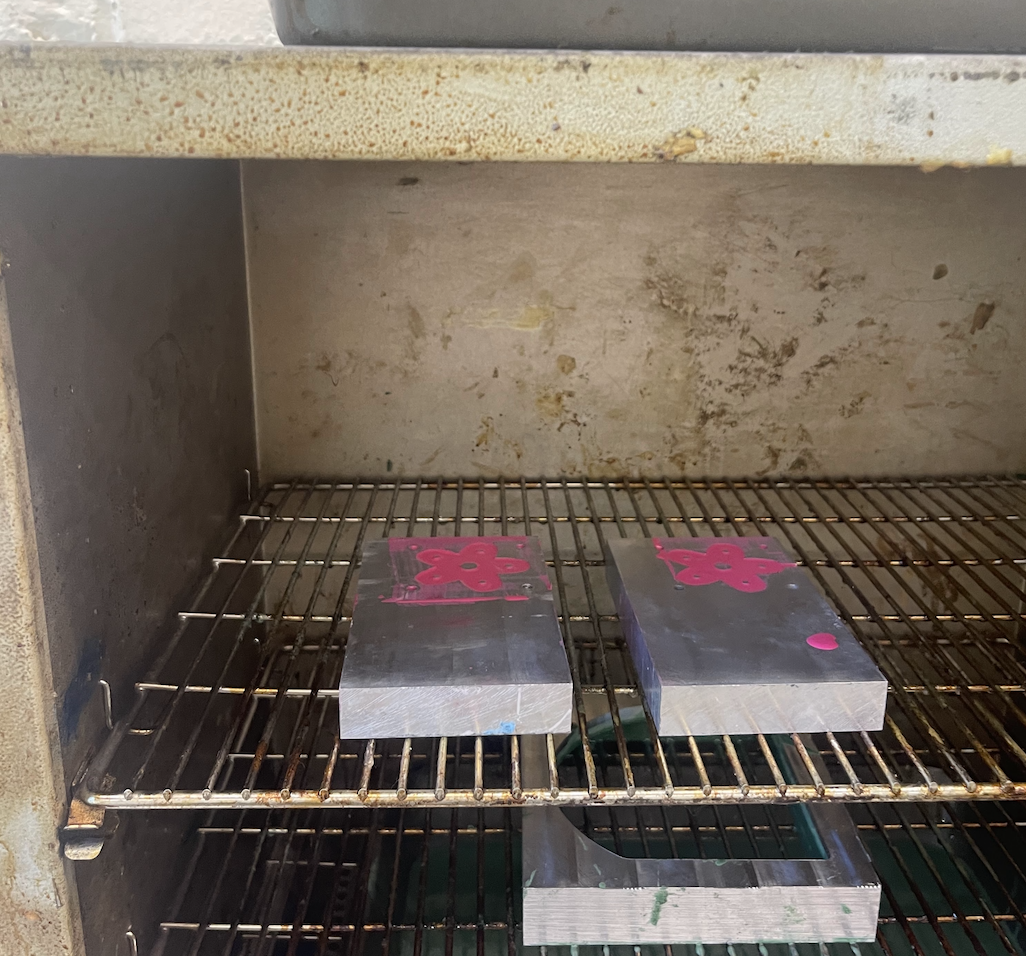

CNC Machining

CNC Machining

Projects for Stanford’s ME 318: Computer-Aided Manufacturing. A handwritten g-code CNC-milled luggage tag. An aluminum topographically-inspired ball bearing maze. An aluminum mold for a silicone flower necklace.

Processes: CAD design, CAM, CNC machining, silicone molding

Timeframe: 10 weeks

Materials: Plastic, aluminum, silicone

Learnings: working with CAM software to understand the exact constraints of CNC machining, silicone casting and moldmaking techniques, iterating on a design several times before cutting chips

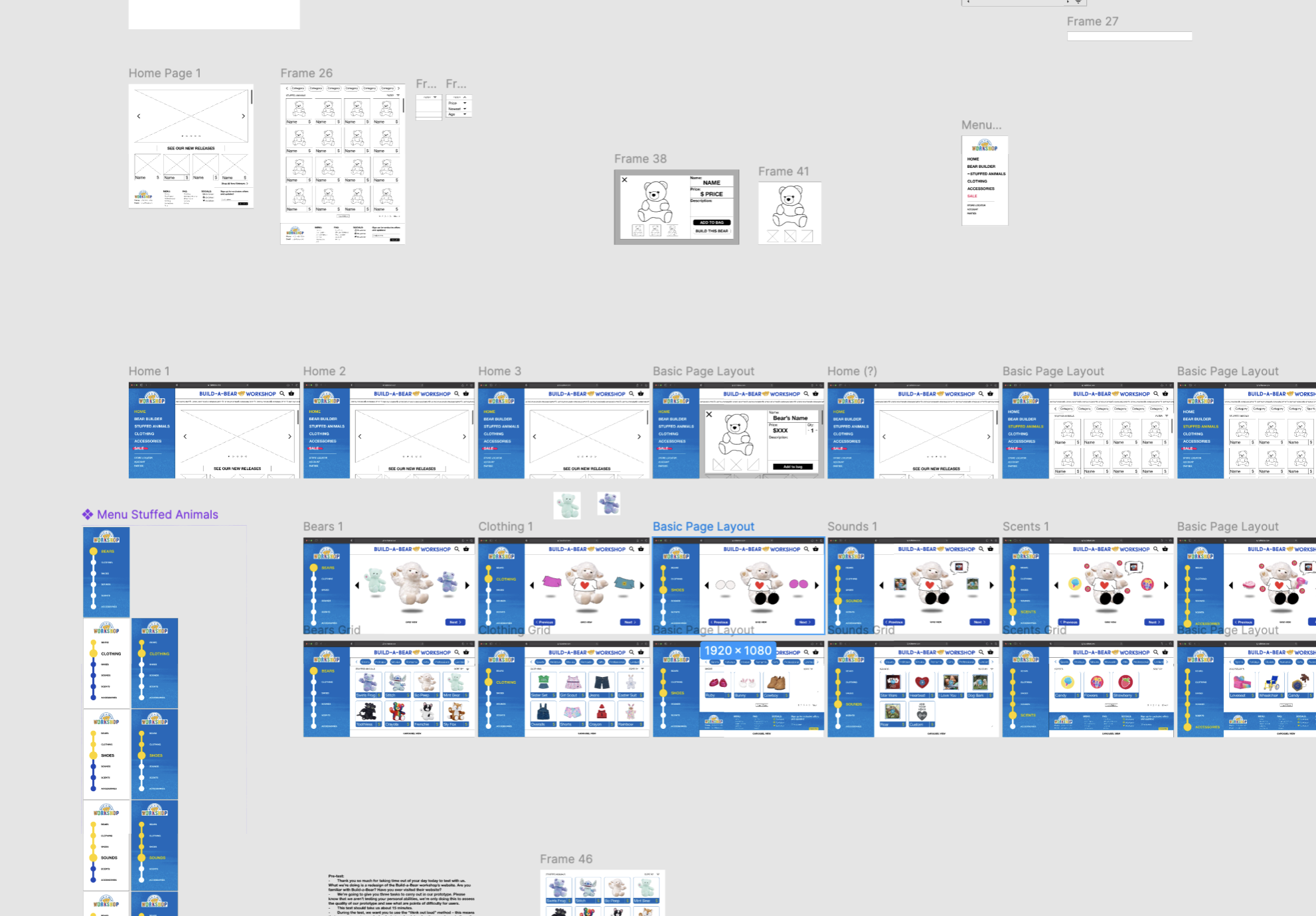

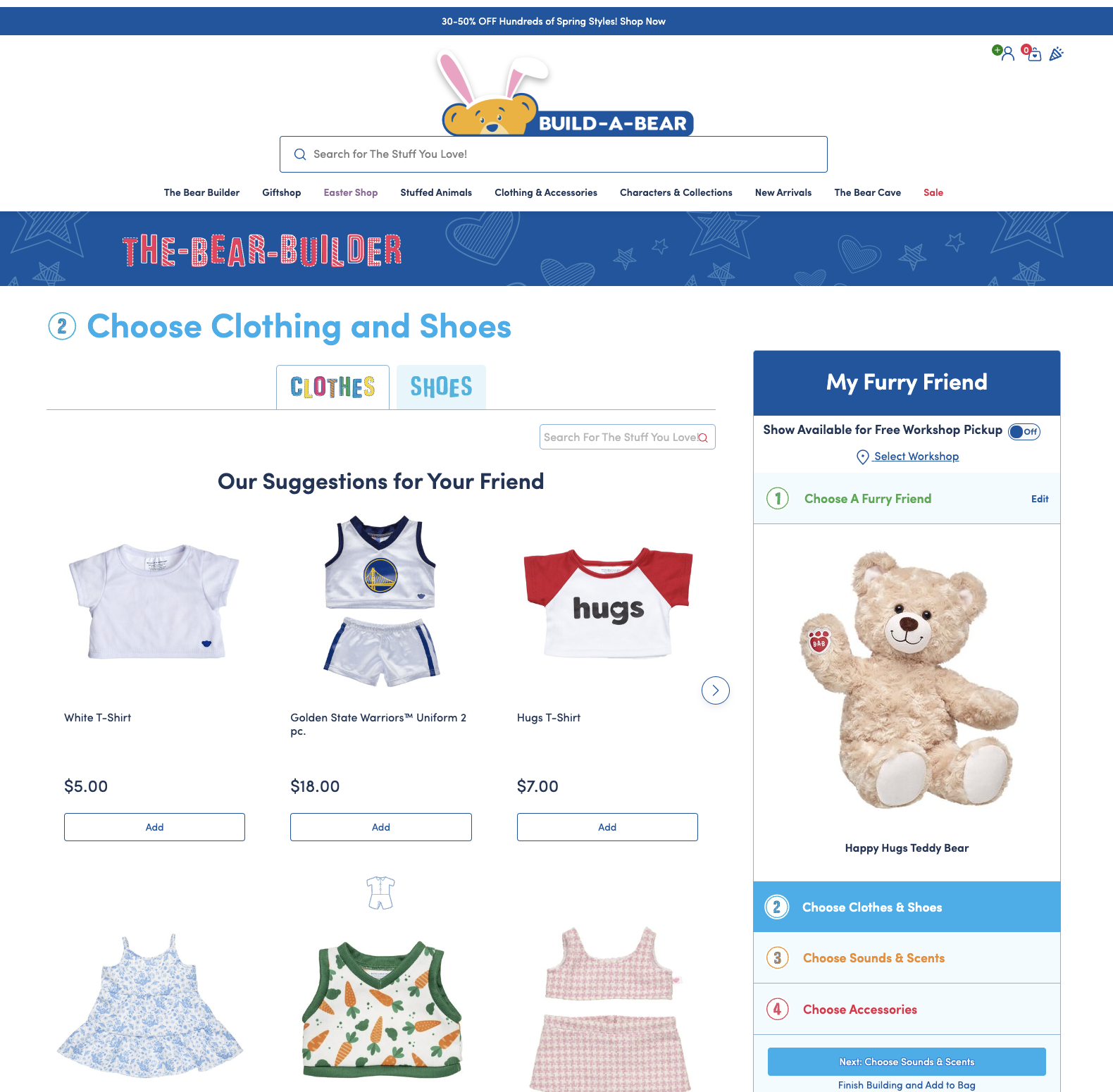

Build-A-Bear Redesign

Build-A-Bear Redesign

Group project for Stanford’s ME 115B: Design for Ergonomics. A redesign of the Build-A-Bear website to make it more interactive and visually engaging. Instead of a static grid of available items, the redesigned website allows the user to try on different outfits on their chosen stuffed animal.

Processes: Figma, user testing, paper prototyping

Timeframe: 10 weeks

Learnings: introduction to web design and UX design, sketching before moving digital, interviews of users are more useful than your own intuition